Why we love Carbon Fiber for

We believe in and love working with and designing products manufactured from Carbon Fiber. Read more about what makes it special and unique and why the performance of a Carbon Fiber product is so advanced when compared to other materials.

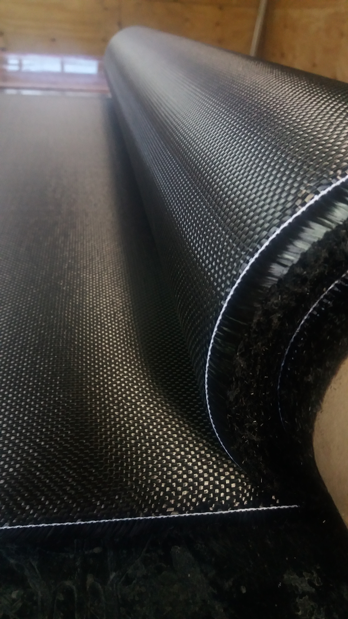

As in any industry, there are top-class manufacturers of Carbon Fiber and there are also many manufacturers who are producing more economical sub-standard carbon fiber. The only way to tell the difference is stress or load, two of the factors that come into play while freediving or spearfishing. especially at depth. We carefully select our Carbon Fiber suppliers and the following is a description of what we look for in a carbon fiber supplier when selecting our materials:

While originating as primarily an aerospace material, carbon fibers are used today in a wide variety of industrial and recreational applications as well such as fin blades and spearguns . Actually, the same substance used to make sweaters, blankets and other familiar things in life is also behind this cutting-edge material "carbon fiber."

The two key features of carbon fiber are its excellent strength and light weight. The specific gravity of carbon fiber is around 1.8, which is approximately one-fourth of iron's specific gravity of 7.8. Carbon fiber is also significantly lighter than aluminum and glass fiber having a specific gravity of 2.7 and 2.5, respectively.

In addition, carbon fiber has excellent strength and modulus of elasticity: its specific strength calculated by dividing the tensile strength by the specific gravity, is approx. 10 times the specific strength of iron, while its specific modulus of elasticity calculated by dividing the modulus of elongation by the specific gravity, is approx. 7 times that of iron. That's why carbon fiber is a favorite lightweight material to replace conventional metal materials. Carbon fiber has various other characteristics such as not failing due to fatigue, not rusting, and is chemically and thermally stable. It is a highly reliable material whose characteristics are stable over long time even under severe conditions.

The most familiar use of Carbon Fiber has to be in aircraft like the Boeing 787 and other jet airplanes that are significantly lighter, more fuel-efficient, more flexible in terms of design, and more comfortable, thanks to their body, main wings, tail plane and other structural members made of carbon fiber composite materials benefiting from the above mentioned characteristics of carbon fiber.

Our carbon fiber manufacturers product is globally recognized for their outstanding performance, quality and processing consistency, making them the preferred choice of designers, engineers and fabricators worldwide.

When manufacturing Spierre fin blades one of the key elements that we take into consideration are the hours spent exerting energy underwater and the efficiency of the fin blade. On this score Carbon Fiber is the most light-weight of all the composites and combining the Pure Carbon fin blades or Carbon fin blades with a good quality, well-fitting lightweight foot pocket such as Pathos or Mares will ensure that the light-weight properties of the Carbon Fiber is maximized to your benefit while diving, meaning less strain on your legs and helping to conserve valuable oxygen underwater.

Added to that, the excellent strength means that for it's light-weight properties, the Pure Carbon Fiber and Carbon Fiber fin blades are remarkably robust and we have divers who have been diving with the same pair of Spierre fin blades for over 12 years!

Also in Spierre News & Updates

Spierre Fin Blades Custom Options Explained

Spierre Fins Production

Each set of Spierre Fin blades, is custom handcrafted to order and the production time will take about 5 - 6 weeks (depending on the volume of orders in production when placing your order).

If you have a trip coming up, or need your order sent to you sooner than this, please mail us at info@spierre.com to find out if we can put a rush on your order.